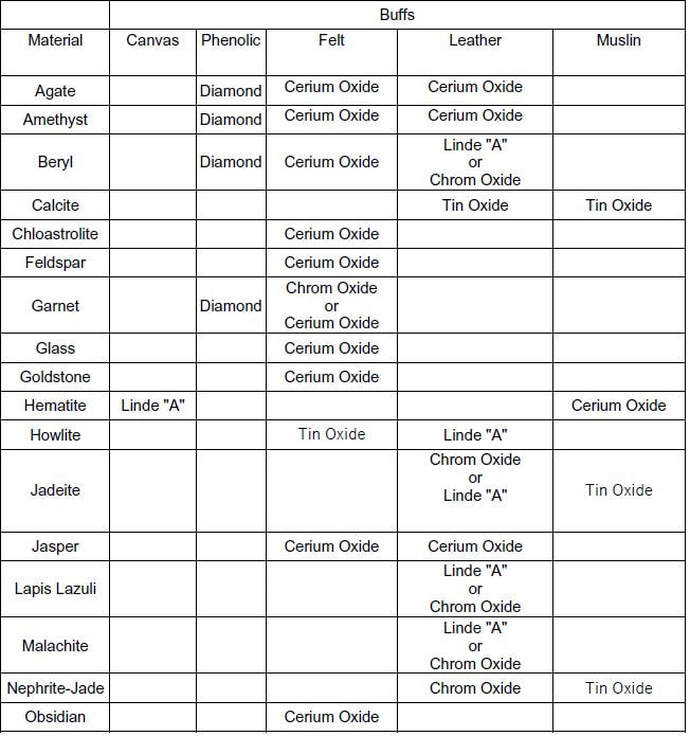

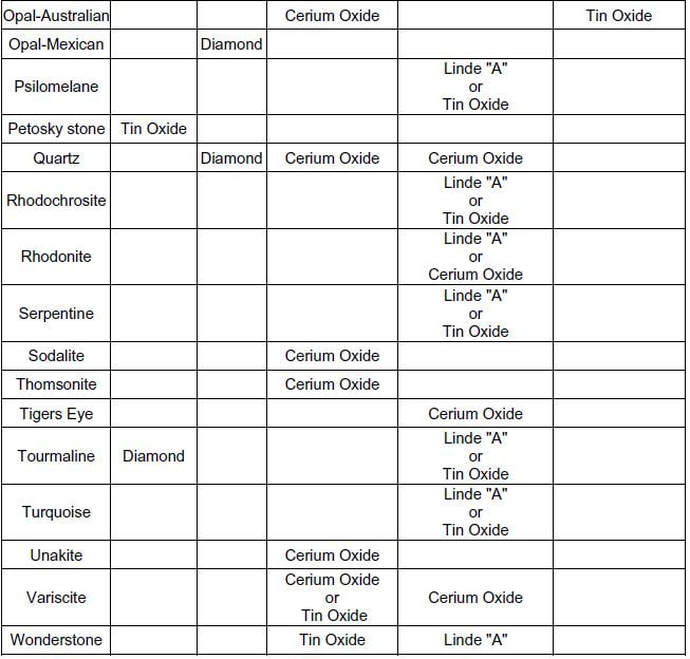

Cabochon Polishing Chart

If you want to get the best polish possible for your stone, you need to use the correct combination of buffing wheel (of disk) and polishing compound. Some stones will polish equally well with several combinations.

Polishing does not remove any material from the surface. If scratches develop, the stone must be re-sanded.

Polishing does not remove any material from the surface. If scratches develop, the stone must be re-sanded.

BUFFS

Canvas: Canvas is useful when polishing heat-sensitive stones because it develops very little friction.

Phenolic: Phenolic tools or phenolic lap disc (cab laps) are useful when impregnated with diamond grit.14,000 Micron (pre-polish) or 50,000 Micron (polish) diamond compound can be applied to the surface of the gemstone and worked with a phenolic carving tool. It can also be applied to the surface of a phenolic lap disc and worked with the gemstone mounted at the end of a dop stick. The diamond will charge the phenolic plate making smoothing and polishing easier.

Felt: Felt is useful for polishing glass and stones of even texture. It is not recommended for gemstones that under cut. Friction on felt generates heat.

Leather: Leather is a versatile buffing material that is both efficient and economical. Leather generates heat, but not as much as felt.

Muslin: Muslin buffs are recommended for soft stones and gems that are heat sensitive.

POLISHING COMPOUNDS

Cerium Oxide: Cerium oxide will polish at a faster rate than conventional polishing compounds and produce a superior optical lens surface with no staining or caking. Because it will polish faster, a lower concentration can be used. It is recommended for use on leather, felt, polyurethane foams, and thermoplastic polishing pads. It is a favored polish for quartz type minerals and other gemstone types. It is not recommended for gemstones that will under cut.

Linde "A": A .3 micron aluminum powder that is carefully graded for uniformity of grain size. It is excellent for polishing stones that will under cut. Excellent for hard to polish stones.

Chrom Oxide: Chromium oxide is a hard polishing agent. It is green in color and stains badly. It is useful for polishing jade and stones that will under cut.

Tin Oxide: Tin oxide is an excellent general-purpose polish. It is used to provide a final high gloss finish.

Canvas: Canvas is useful when polishing heat-sensitive stones because it develops very little friction.

Phenolic: Phenolic tools or phenolic lap disc (cab laps) are useful when impregnated with diamond grit.14,000 Micron (pre-polish) or 50,000 Micron (polish) diamond compound can be applied to the surface of the gemstone and worked with a phenolic carving tool. It can also be applied to the surface of a phenolic lap disc and worked with the gemstone mounted at the end of a dop stick. The diamond will charge the phenolic plate making smoothing and polishing easier.

Felt: Felt is useful for polishing glass and stones of even texture. It is not recommended for gemstones that under cut. Friction on felt generates heat.

Leather: Leather is a versatile buffing material that is both efficient and economical. Leather generates heat, but not as much as felt.

Muslin: Muslin buffs are recommended for soft stones and gems that are heat sensitive.

POLISHING COMPOUNDS

Cerium Oxide: Cerium oxide will polish at a faster rate than conventional polishing compounds and produce a superior optical lens surface with no staining or caking. Because it will polish faster, a lower concentration can be used. It is recommended for use on leather, felt, polyurethane foams, and thermoplastic polishing pads. It is a favored polish for quartz type minerals and other gemstone types. It is not recommended for gemstones that will under cut.

Linde "A": A .3 micron aluminum powder that is carefully graded for uniformity of grain size. It is excellent for polishing stones that will under cut. Excellent for hard to polish stones.

Chrom Oxide: Chromium oxide is a hard polishing agent. It is green in color and stains badly. It is useful for polishing jade and stones that will under cut.

Tin Oxide: Tin oxide is an excellent general-purpose polish. It is used to provide a final high gloss finish.